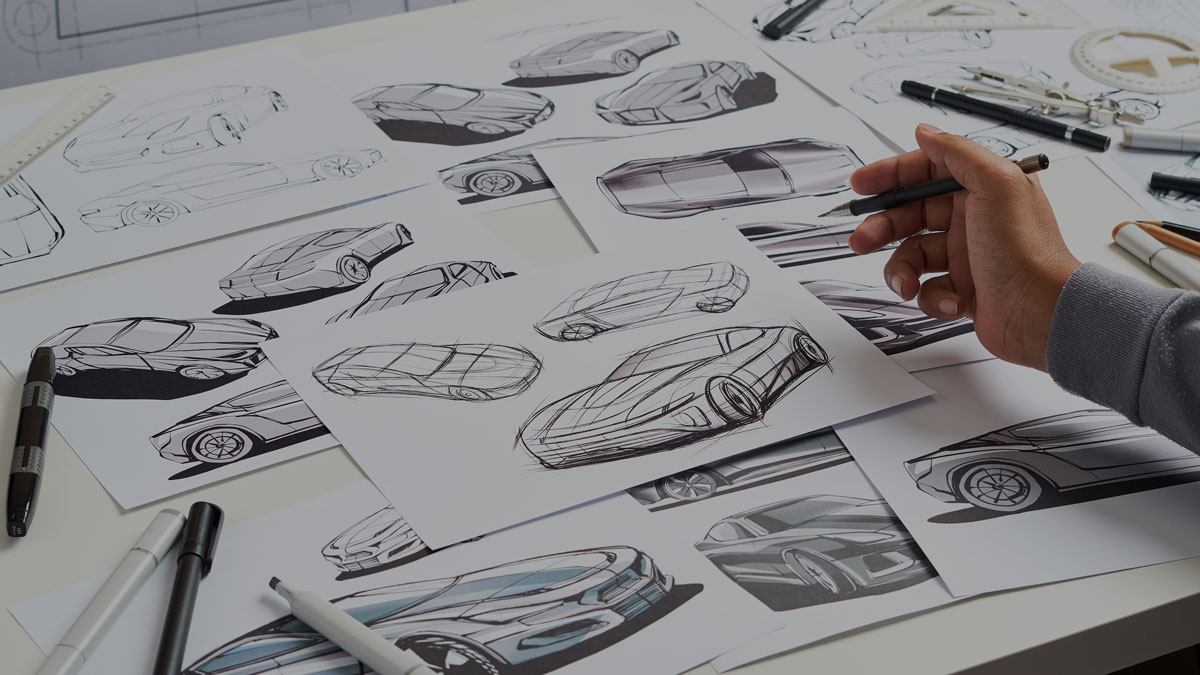

Precision is an integral part of design. But while it’s easy to visualize precise results, communicating them and materializing them are processes riddled with hurdles. In this article we will examine the problems that interfere with achieving high design precision and we will explore ways to overcome them, with special reference to the automotive design industry.

©kustvideo / stock.adobe.com

The Current Understanding Of Design Precision

Precision is and has always been an issue in design, since it plays a fundamental role in communicating and materializing concepts. But as many designers know, achieving precision is more than just a technical skill. It requires bridging the gap between the conceptual and the material expressions of an idea.

Bridging that gap hinges on the tools and processes available at any given time, since certain tools and processes allow for levels of precision that match the designer’s original concept. So where do we stand today?

Let’s take the automotive design industry as an example. Within this sector, clay modeling is still a common practice, which seems paradoxical considering that automotive is a tech-driven industry. Clay may be low-tech, but its malleability allows designers to achieve surgical precision, assuming they have the right tools and expertise. However, this approach has shortcomings that impact precision.

Issues That Interfere With Design Precision

One of the main drawbacks of the current system is the time involvement required in achieving the desired level of design precision, and not only in terms of the process itself. Gaining the necessary experience to achieve competitive precision levels in clay modeling requires a substantial time investment too.

We must also consider that the system in place today may have outrun its useful life, since it originated in times when there was no defined design system as we understand it today. But as corporate and design systems evolved, design became enmeshed in a layered management system where loops of change and iteration are part of the process.

Navigate change and iterations to improve precision entails lengthy discussions across the corporate hierarchy. And acting on errors or making improvements requires a substantial time investment, which lengthens the process even further due to the time involved in reaching consensus. This is particularly evident in the automotive industry, where gaining a competitive advantage in precision often entails increasing complexity and dependencies along the chain.

This begs the question: Is this all we can aspire to?

Taking Design Precision To The Next Level

Aspiring to more and better is innate to humans and this desire has always been a driver of innovation.

Since theoretically speaking, higher design precision levels are always imaginable, it’s only logical to question: how useful are the current tools and processes we use in design? And because design on the whole is getting increasingly precise, the general public is developing a trained eye to spot flaws or imprecisions, which raises the bar for designers.

We have already said that design precision is goal-oriented, since it aims to trigger the mechanisms through which the end user chooses one product over another. In the current scenario, designers need more than a trained eye and fine communication skills to fulfill precision expectations.

In our view, we need to approach design precision under a different conceptual paradigm. This means reviewing our understanding of design and its constituent parts as a strategy, instead of simply as a means to an end. This could allow designers to overcome one of the main hindrances affecting the industry today (i.e. the time involvement factor), as long as the shift is supported by a qualitative improvement in the tools available.

Having access to more precise tools right from the start would result in significant time savings (up to six months according to our estimates). These tools would also:

- Allow for more precise iterations of a concept.

- Allow for more variance and therefore increase the opportunities for design freedom and innovation.

The good news: This type of technology is already available

For example, virtual reality modeling tech can propel design by enabling precision levels we could hardly imagine only a few years ago. What’s more, using this technology as an integral part of design strategy could do away with the obstacles that currently hinder the design process. How?

First, mistakes would no longer be costly and catastrophic. VR modeling could add a safety layer to design experimentation and boost creativity, since any flaws flagged during the design process wouldn’t equal wasted time and resources.

Under the current paradigm, precision is a control tool that aims for and reinforces safety ‘ safety understood as the need to bet on a single design option for operational reasons. But VR technology eliminates this limitation and instead turns the focus over to variance, allowing multiple design options to be worked on simultaneously. In summary, embracing VR modeling could turn variance into the new safety.

Secondly, the design precision inherent to VR tech could streamline the decision-making process at management or executive level. This technology can instantly communicate concepts and results with extreme precision, making it easier to accept and move forward or to discard an idea before making an investment. Therefore, VR modeling could have important monetary implications for design companies.

And lastly, bringing VR tech into the equation could address communication gaps and help all stakeholders be on the same page during the product development workflow.

Conclusion

Design precision is a reflection of the innate human drive to strive for greatness. The technological advances that mark our era can help advance this drive even further, by removing the limitations that currently impact the design process. Specifically, the adoption of VR technology can bring about transformative and long-awaited changes to the entire design industry. Will you be joining the revolution?